MC200 milking controller unit combines advanced technology with the ease of use and installation.

MC200 is a compact product, consisting of a display which is directly integrated with the pulsation unit.

MC200 was created to control single milking clusters through the close connection between the automatic TCR and the milk flow-controlled pulsation unit.

MC200 shows the farmer the milk production and it represents the ideal solution to update the existing milking parlors with a small investment.

Choosing MC200 Milkline you will have:

-

an easy and efficient system with minimum investment

-

ease of installation in preexisting milking parlors

-

“clever” milk flow-controlled pulsation

-

automatic TCR and pulsation stop

-

warnings of low production and cluster fall-offs

-

ready to be connected to Milcon herd management unit

-

easy and flexible configuration through PalmTM without opening the pulsator

حلب الآلات والمعدات صالون

Milking controllers

Milkline is innovative, finding cutting edge solutions tailored to the farmer's real needs and designed to guarantee him safe production and high quality.

Milkline, with its automatic milking controllers, provides the tools for a more effective and profitable work.

Milking controllers

MilproRed

MC200

MilproRed is a simple milking controller unit that provides the farmer with all the information about herd productivity.

The three fundamental elements of the unit (controller, automatic TCR and pulsation) are closely linked guaranteeing optimal data processing reliability and perfect performance of milking processes.

Choosing MilproRed Milkline you will have:

-

simple control through a single BIG button

-

infrared milk flow sensor and production gauge FFS30

-

flow-controlled pulsation through FFS30 Free Flow Sensor

-

specific stimulation function

-

milk production, flow and milking time shown on display

-

low production and cluster fall-off warnings

-

automatic TCR with adjustable milk flow values

-

programmable pulsator through Palm®

-

fully compatible unit for the connection to MilconHM

ED200

ED200 is an advanced technology product that manages production, pulsation and TCR in a unique system.

The unit is ergonomic and easy to install, and it adapts easily to any type of milking parlor. Although requiring a small investment, ED200 guarantees perfect control over the milking unit.

Choosing ED200 Milkline, you will have:

-

an advanced unit with minimal investment

-

the possibility to install it either with or without cabinets

-

simple installation in existing milking parlors

-

guaranteed milking with minimal maintenance requirements

-

reduced milking time, more comfort for the operator

-

optimal animal wellness, by eliminating over-milking

-

display of warning and alerts during milking

-

wide screen display to clearly show milking information

-

high flexibility in TCR management

-

conductivity detection through the new optical sensor FFS30 COND

-

suitable to be connected to MilconHM, real-time milking control and herd management system

MilproP4C

MilproP4C is a very advanced technology system that allows the farmer to have complete control over the milking process.

This product peculiarity and high efficiency are due to the presence of innovative functions for milking per single quarter.

The P4C system consists of three fundamental elements:

-

Milking cluster – Milpro Dynamic P4C equipped with:

-

dynamic flow separator with built-in four conductivity cells

-

deflector, which neutralizes the typical turbulent milk flowing from the liners to the claw, thus avoiding the “spray effect” between the single teats

-

silicone liners Milkline Milpro

-

-

Electronic pulsator – Servo Pulse P4C with four independent pulsation channels that allow to choose among different types of milking (front - rear, left - right)

-

Controller – MilproP4C closely linked to Servo Pulse P4C and e Milpro Dynamic P4C, to control all the functions of the milking process.

Choosing P4C you will have:

-

milk flow-controlled pulsation with automatic stimulation function

-

real milking stop function per single quarter reducing the related overmilking effect

-

mastitis warning – capability to detect subclinical mastitis per single quarter reducing business expenses and ensuring animals wellness

-

complete recording of milking data

-

total compatibility with MilconHM herd management system

Automatic TCRs

The Teat Cup Removal system allows the operator to save time and it ensures that milking process is fully respectful of the udder health.

Automatic management of the TCR allows adjustment of milking features according to the specific needs of the stall.

ML MPD AUTOSTART

The automatic ML MPD AUTOSTART teat remover was created to provide the operator with the maximum ease when starting milking operations.

The “Autostart” function allows the milking to start by simply lifting the milking cluster.

Benefits for the farmer:

-

ease to use

-

easy and quick installation

-

very low maintenance times and costs

-

animal comfort during milking phase

The automatic ML MPD AUTOSTART teat cup remover consists of:

-

stainless steel piston

-

single control unit (to manage all the TCRs installed simultaneously)

-

flow sensor

-

command button

It is possible to set all working parameters by a single “Master Controller” power unit, connected online to every TCR installed:

-

milk flow first waiting time

-

minimum al milk flow level to start cluster removal

-

delay time for cluster removal

-

milking stop function in case of cluster fall-off

-

residual milk removal from milking unit

All operations (START-STOP-MANUAL-AUTOMATIC) are controlled by a simple and wide push button.

A led in the cylinder head informs about the TCR working status:

ML MPD NEW

The automatic ML MPD NEW teat cup remover was created to provide the operator with the maximum ease when starting milking operations.

Benefits for the farmer:

-

ease to use

-

easy and quick installation

-

very low maintenance times and costs

-

animal comfort during milking phase

The automatic ML MPD NEW teat cup remover consists of:

-

PVC piston

-

single control unit (to manage all the TCRs installed simultaneously)

-

flow sensor

-

command button

It is possible to set all working parameters by the “Master Controller” power unit, connected online to every TCR installed:

-

milk flow first waiting time

-

minimum milk flow level to start cluster removal

-

delay time for cluster removal (vacuum to claw interrupted)

All operations (START-STOP-MANUAL-AUTOMATIC) are controlled by a simple and wide push button.

A led in the cylinder head informs about the TCR working status:

Positioning arms

These are steerable devices used to support milk and pulsation hoses.

They can be used in any type of milking parlor.

-

Stainless steel/plastic positioning arm

-

Stainless steel positioning arm

Pulsators

In order to perform a correct milking respecting the animal , it is necessary to apply a pulsating vacuum to the teats which perfectly imitates the action of a calf sucking. Milkline pulsators are specifically designed to best adapt to all types of milking providing optimal pulsation parameters for the health of the udder.

Milkline provides a range of pneumatic and electronic pulsators:

-

pneumatic pulsators are the ideal solution for bucket and mobile milking systems or anytime it is impossible to use a stable and sufficient power supply.

-

electronic pulsators, compared to the pneumatic ones, allow better accuracy in pulsation rate and ratio.

ML120

ML120 is the pneumatic pulsator which guarantees milking precision and long term reliability. It is made and tested in Italy following the strictest company regulations in compliance with ISO standards.

Made from high resistent polymers, it guarantees high wear resistance.

It needs minimal maintenance, due to its dry operation and to the innovative coupling SUREMATCH® system between the internal parts.

The RETROFIT® air filtrering system guarantees a 50% higher filtering capacity compared to the market standard.

Benefits for the farmer:

-

designed to be a long-lasting product

-

fast, uniform and constant milking

-

adjustable frequency range of 50÷180 PPM

-

operating vacuum range of 35÷50kPa

-

internal parts 100% self-lubricating

-

low stress for the animal

SmartPulse

Milkline proposes two types of electronic pulsators in the Smartpulse line:

-

SmartPulse Master

-

SmartPulse programmable.

The Smartpulse line is characterized by easy and efficient components and it allows simple and inexpensive maintenance. The pulsation system is power-assisted through a solenoid controlled silicone membrane. This feature allows a lower energy consumption of and makes the pulsators less subject to mechanical wear.

Smartpulse line Milkline pulsators are extremely silent and equipped with an internal air filter and a connector, which can be easily connected to the air filtration system.

They are easy to clean on-site by drawing water through the pulsation tubes, without any risk of damage to the electrovalves.

By choosing the SmarPulse line you will have a product that is:

-

safe and efficient

-

very silent

-

built-up from few and simple components

-

quick and easy maintenance

-

low energy consumption

With SmartPulse Programmable you will also achieve:

-

independent and programmable pulsation with 8 different rates (from 50 to -80 ppm) and 8 ratios (from 50/50 to 70/30)

-

possibility to program shifted phase for 8 pulsator groups - , cascade system

-

easy programming through the two buttons on the pulsator circuit board

Servopulse P4C

Servopulse P4C is an electronic pulsator with 4 independent pulsation channels.

This pulsator is specifically designed for the Milpro P4C system.

Servopulse P4C is equipped with the 4 new independent channels distributor and allows the management of the individual pulsation for each cluster. Servopulse P4C components are simple and efficient and its maintenance is easy and inexpensive.

The pulsation system is power-assisted through a solenoid controlled silicone membrane. This feature allows lower energy a reduction in electric energy consumption and makes the pulsators less subject to mechanical wear.

Servopulse P4C is extremely silent and is equipped with a connector, which can be easily connected to the air filtration system.

Milk meters and flow indicators

The main function of the milk meters and flow indicators is to measure the productivity of each individual milked cow.

A good production monitoring of each individual animal can help in evaluating the genetic characteristics and wellness of the animal.

By using milk meters the milk yield increases and the work efficiency improves.

FFS30

The extremely compact FFS30 milk meter is combined with our milking controller units (MilproP4C, Milpro Red, ED200) to provide the individual lactating cow production data.

This Free Flow Sensor uses the infrared technology to read production and milk flow, thus no mechanical parts enter into contact with milk and no flow restriction occurs.

The production data can then be processed by our herd management software (Milcon) which analyses data and makes it available for the farmer.

MEL 1000

MEL 1000 is the most reliable ICAR approved electronic milk meter currently available on the market. Made entirely of plastic (polysulfone resin), it guarantees non-toxicity and high mechanical resistance.

This milk meter can be combined with the whole range of our milking controller units (MilproP4C, Milpro Red, ED200), providing lactating cow production data in an easy and complete way.

MEL 1000 is designed for the most demanding farmers who wish to easily control all the production data collected from the milking parlors.

The production data can then be managed by our herd management software (Milcon) which analyses the data and makes them available for the farmer.

Milking clusters

Milkline milking clusters are designed to ensure fast and regular milk flow. Their ergonomic design makes them easy to use by allowing the operator to attach them to the udder with minimal effort. The combination of milking unit components is specifically designed to grant an equal weight distribution.

Classic Line

The milking clusters of the Classic Line represent a good milking, kindness for the udder and simplicity of use.

The black rubber liners Milkline® used are of the latest generation and they respond also to the European requirements in terms of food contact (RAL certificate, BfR). Designed for a perfect fit of the udder and to keep it healthy, this kind of liners stand out on the market thanks to the excellent wear resistance.

The torches are stainless steel light to best balance the milking cluster, to prevent air infiltration and to ensure a good emptying of the milk claw.

The milking tubes are constituted of traditional black rubber of excellent quality. Produced with the best available non-toxic blends, they can boast the RAL certification. The quality of the material used minimizes the possible transmission of unpleasant tastes to milk. This kind of milking tubes are highly resistant to fat migration, that are present in the milk, and to detergents used during the cleaning phases.

The milking claws... the heart of the milking cluster, are all ergonomic and optimally positioned, ideal for each type of udder.

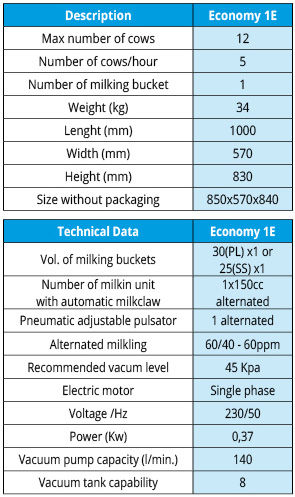

Milkline® offers different types of Classic milking clusters, each of them with specific characteristics to meet the needs of each farmer and they offer the maximum comfort to the operator during milking.

ML / PL milking cluster

The milking cluster with a “standard" claw, with good capacity, suitable for bucket milking systems and portable milking machines.

Equipped with the upper part of plastic material, this milk claw is provided only with shut-off valve.

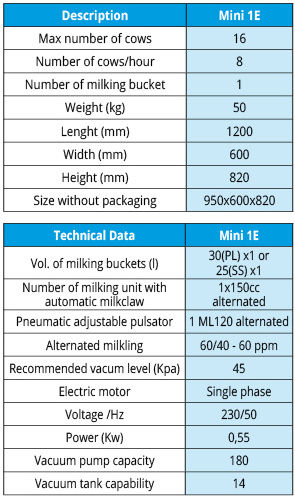

ML / AL Automatic milking cluster

The milking cluster with a "standard" claw, very strong, 300cc, with the upper part of a stainless steel one-piece component.

The claw used on this milking cluster is provided with or without shut-off valve and ø 12 mm or ø 15 mm milk inlet nipples.

ML / AL Maxflow claw milking cluster

The milking cluster with a "very large" claw, specific for cows with high milk flow, very sturdy, 300cc, with the upper part of a stainless steel one-piece component.

The claw used on this milking cluster is provided with or without shut-off valve and with increased milk inlet nipples.

DynamicP4C

The DynamicP4C milking unit is equipped with a patented deflector that keeps milk flow independent per individual quarter, while simultaneously taking a reliable measurement of conductivity through four built-in conductivity measuring cells.

The special deflector shape, combined paired to the separating walls per single individual quarter, prevents the typical turbulencent of the milk flowthat flows from liners to the claw, thus avoiding the occurrence of the mastitis by “impact”contact.

The DynamicP4C line is designed and created to give the best results when used with the specific silicone liners and teat cups shells, which are patented to provide special protection and high resistance.

Milpro Dynamic

Milpro Dynamic milking unit is equipped with a patented deflector that allows a milk flow dynamic separation of each quarter.

The special deflector shape, combined to the separating walls per single quarter, prevents the milk from getting into the bowl with the typical turbulence and forces it to flow along the claw walls thus avoiding the occurrence of mastitis by “impact”.

The XF milk bowl allows a very high milk flow, a better vacuum stability and minimal vertical encumbrance of the milking unit, due to the reduced outlet angle.

Silicone liners optimal use is successful only thanks to the patented combination of teat cup, liner, protection ring that guarantees high resistance and long duration.

Liners

Milking liners need to be chosen according to the morphological features of the udder.

Milkline offers a wide range of liners made from top quality materials. Milkline liners are up to the European safety standards for food contact surfaces (RAL certification, BfR).

Milkline liners stand out in the market for being very adaptable to the udder of different dairy breeds and for being highly wear resistant.

Rubber liners

The profitability and the quality are the main goals of dairy production. Choosing the right liners is fundamental because they are the only parts coming into close contact with teats. Aware of the importance of this choice, Milkline provides the farmers with a wide range of liners made from the best blend available on the market.

Milkline liners are very elastic and extremely adaptable to any type of udder. The product range includes different models, designed to suit the different teat morphologies (long, short, thin and wide teats).

Advantages:

-

elasticity

-

easily adaptation

-

less slip

-

resistant

Milpro Milkline®

Milpro Milkline liners belong to a new generation of milking components. Milkline uses a unique silicone blend for the Milpro liners, that thanks to their extraordinary elasticity ensure a natural milking by wrapping the teat softly. Milpro liners are characterized by a perfectly smooth inside surface that is also hygienic, effective, durable, gentle to the teat, and resistant to the hot water washings.

Advantages:

-

maximum hygiene

-

perfect adherence

-

elasticity and softness

-

high adaptation ability

-

no narrowing of the nipple

-

optimal adherence even at a low level of vacuum

-

long duration maintaining good performance

-

no negative impact on the natural defence ability of the udder

Milk transfer

By milk transfer in a milking system we refer to the entire way the milk has to travel from the moment it is extracted from the udder to the milk receiver.

In order to produce quality milk, it is necessary to be very careful in planning and installing the milk line. The components have to be made of non-toxic, high performance, high resistant materials in order to guarantee a constant and fast transfer, with no bio-chemical alterations of the end product.

Receivers

With the milk receivers the milking process is extremely efficient due to a correct flow of the milk. Milkline proposes a wide range of milk receivers which are available in various sizes to meet the needs of any milking system. They are made of glass or stainless steel. All Milkline receiver units are equipped with transparent sanitary traps and level sensor (electrode or float); the sanitary traps can be washed with the milking plant at the end of each milking process.

Glass receiving units

Milkline proposes a wide range of transparent pyrex glass receivers suitable for small to medium size milking units (up to 10 milking units).

Easy to install through a full stainless steel wall-mount.

Complete accessories: stainless steel milk pump, self cleaning transparent sanitary trap, automatic level controller.

Product range available from 23 to 50 liter both in the STANDARD and ECONOMICAL version.

Stainless steel receiving units

Milkline stainless steel receiving units represent the ideal solution for medium to large size milking units (from 10 milking units on).

They are available from 32 to 120 liters, either in a vertical or horizontal stand.

Complete accessories: stainless steel milk pump, self cleaning transparent sanitary trap, automatic level controller.

With the professional stainless steel receivers Milkline® guarantees fewer vacuum fluctuations.

Milkline milk pumps

The role of these pumps is to transport milk from the milk receiver to the cooling tank without altering the quality of the product. Transportation has to be quick and gentle so that no physical-chemical alterations in the milk occur. Milkline milk pumps are available in various models and are suitable for any type of milking plant.

Milkline centrifugal pumps are available in various model depending on the capacity needed.

Membrane milk pump DE15 is specifically designed for Quality Milk production; it guarantees better cheese making due to gentle transportation, without shaking the milk.

Milk transportation control system

The use of centrifugal milk pumps is one of the causes for the increase of free fatty acids in milk. High rotation speed, together with the presence of air in the pipes, causes “shaking” (lipolysis) with a consequent negative impact on milk yield.

The milk transportation control system substantially reduces this phenomenon by adjusting pump rotation speed according to the real needs of the milking plant.

Variospeed Level

The use of centrifugal milk pumps to transfer milk from the milk receiver to the cooling tank is one of the causes for the increase of the free fat acids in milk.

High rotation speed, together with the presence of air in the pipeliness, causes “shaking” (with lipolysis) and has a consequent negative effect on the final yield of the cheese making.

The control system Variospeed substantially reduces this phenomenon, adjusting the milk pump rotation speed according to the real needs of the milking plant.

Variospeed is the milk transportation control system proposed by Milkline. It allows the full milk pump capacity available during milk flow peaks and the washing phases, while the pump automatically reduces rotation speed in case of regular milk flow.

Advantages:

-

less milk shaking and consequently higher yield of cheese making

-

more efficiency of milk filter

-

less wear of pump, seals and no-return valve

-

gradual start and stop

-

less power consumption

Different types of Variospeed:

Vacuum Systems

The production of vacuum is one of the key points for the proper functioning of a milking plant. Vacuum generating and control systems must guarantee total respect for the animal's health.

Vacuum is used in different milking stages:

-

milk extraction during milking

-

vacuum operated pulsators, which guarantee the massage-milking alternate phases

-

milk transfer from pipelines to milk line

-

cluster removal

-

diaphragm valve operation in many parts of the milking plant.

The vacuum also determines the mechanical action of the milking plant cleaning solutions.

A milking plant must have a suitable, stable and continuous vacuum level in order to avoid excessive teat stimulation.

Due to the special manufacturing procedures and strict controls, Milkline vacuum pumps guarantee, at equal power absorption, higher flow rate without compromising reliability and durability.

Milkline vacuum units can meet the requirements of any milking plant.

Milkline vacuum units' compact and practical design allows easy installation and minimal servicing.

Vane vacuum units

Milkline provides different types of vane vacuum units among which include:

-

dry vacuum units PVU

-

oil-lubricated vacuum units PVU-L

-

oil-lubricated vacuum units SILENT

Vane vacuum units consist of a rotor equipped with mobile vanes that eccentrically rotates inside a stator, producing and maintaining the vacuum.

Milkline vacuum units PVU-L

Milkline vacuum units PVU-L are characterized by their function of constant lubrication. They are provided with or without a vacuum tank. Milkline vacuum pumps PVU-L guarantee reliability, flexibility, efficiency and high performance. Motor coupling is realized by drive pulleys and belts protected by a special carter for the operators' safety. All the PVU-L units are equipped with a simple belt tension adjustment mechanism. PVU-L units are always provided with a capillary lubricator. The pumps have a 2800-3000 l/m capacity.

Advantages:

-

reliability

-

high performance

-

efficiency

-

very limited noise

Direct-drive oil-lubricated vacuum units – SILENT

Milkline Silent vacuum pumps are designed and created to be efficient, silent, and dependable. The technology with direct coupling (without belts) makes them very compact and guarantees higher performance with less energy consumption. The pumps have a nominal capacity ranging from 460 to 1600 l/min (at 50 kPa). These vacuum units are perfect for couple use.

Advantages:

-

extremely silent – accurate metal workings enable to lower noise to 72 dB (A), compared to 80 dB (A) of traditional belt-drive pumps

-

maximum efficiency

-

reduced operating costs

-

compact – they are designed for compact mounting to take up less space

Dry vacuum units PVU

Milkline vacuum units PVU are characterized by a completely dry operation due to the special structure of the pumps. Maintenance is easy and quick, and energy consumption is particularly low. The units are always equipped with vacuum gauge (vacuum meter) and integrated vacuum tank to guarantee a constant and dependable vacuum level.

The pumps have a 140 to 250 lt/min capacity.

Advantages:

-

low energy consumption

-

vacuum level measurement and regulation

-

Oil-Free Dust Free (no oil released in the atmosphere)

-

very limited noise

Milkline vacuum lobe units LVU

Milkline vacuum lobe pumps LVU are valued for their solidity and high performances. They are a long lasting and low maintenance product. Milkline vacuum lobe pumps LVU are very efficient and eco-friendly. The pumps operate with two twin rotors rotating in opposite directions inside the cylinder. Milkline vacuum lobe units LVU do not need oil. The product range consists of 3 models with a nominal capacity ranging from 2100 to 3000 l/min.

Advantages:

-

eco-friendly

-

efficient

-

long-lasting

-

low maintenance

Water-Ring Vacuum units Milkline WVU

The water-ring vacuum pumps Milkline WVU, in addition to the simplicity and robustness, are distinguished by their low operating temperatures and the less noise level. The absence of polluting emissions also make them eco-friendly.

The pumps WVU, during operation, must be always supplied with the operating fluid to compress the air and remove the heat generated.

Milkline offers 3 kinds of water-ring vacuum pumps WVU with capacities between 500 and 2400 l / min.

Advantages:

-

noiseless

-

low operating temperature

-

no polluting emissions

Vacuum control systems

They are systems that accurately adjust the pump speed ensuring optimal vacuum levels while using minimal energy consumption.

VarioSpeed VCU Easy

Inverter VarioSpeed VCU Easy is a continuous control system that allows to produce the necessary amount of vacuum for the milking plant by adjusting the vacuum pump speed.

A sophisticated digital vacuum meter constantly measures the milking plant vacuum level, and the inverter maintains the set value by either increasing or decreasing the vacuum pump rotations according to the real needs of the different milking and cleaning phases.

In this way, the inverter considerably reduces vacuum fluctuations in the milking plant, while achieving evident energy savings and dramatic noise reduction.

VarioSpeed VCU Easy is available for different power ranges and different configurations of vacuum systems, and it is suitable to manage one or two vacuum units at the same time.

The advanced control software is already optimized to easily set the different milking vacuum levels, which can be simply selected by operating directly on a specific selector on a comprehensive and easy-to-read control panel.

VarioSpeed VCU allows a drastic reduction in the milking system's energy consumption, saving more than 50%.

VarioSpeed VCU Easy is suitable for all types of vacuum units.

Advantages:

-

it can manage two vacuum units

-

energy saving

-

reduced noise

Vacuum accessories

Vacuum fluctuations can cause pain to the teats and facilitate the passive transport of micro-organisms.

In order to enhance efficiency, Milkline® proposes various products to adjust vacuum level and optimize the operation of vacuum pumps.

Cyclone Oil Recirculation system

Cyclone Milkline system consists of a silencer that allows automatic oil recovery, filtration and reflow. The pumps require minimal maintenance and an oil change only after long intervals. Cyclone is suitable for the PVU-L units.

Advantages:

-

substantial reduction of oil consumption

-

eco-friendly (Cyclone lowers the amount of oil released in the air)

-

better performances

Oil pumps Milkline - BLU POWER

In order to optimize the operation of vacuum pumps, Milkline® suggests using BLU POWER oil.

Milkline® original Blu Power oil is specifically designed to guarantee the correct operation of the oil-lubricated vacuum pumps, to avoid premature wear of the moving parts.

Its main feature is the low vapour pressure and thus low gas formation and steaming.

Milkline provides two types of BLUE POWER oil: standard and winter type for low temperatures seasons.

Advantages:

-

excellent lubrication capacities

-

minimal oxidizability

-

low vapour pressure (even at high temperatures)

Vacuum Regulator

The Vacuum Regulator is one of the most important parts of the milking parlor, because it maintains a stable vacuum level immediately compensating the air entrance which may occur during normal milking operations. The regulator consists of an automatic valve that is designed to maintain a constant vacuum level through the entire milking plant.

Milkline provides a wide range of regulators, which can compensate as quickly as possible any vacuum variation in the system, favouring good udder conditions.

Servo-vacuum regulators

Milkline servo-vacuum regulators for vacuum systems are able to reacts instantly to the minimal fluctuation in vacuum in the system. They are equipped with a sensor that makes them more sensitive and reactive.

They guarantee a constant vacuum level allowing efficient and regular milking. Milkline servo valves have a 1.500 up to 4.500 l/min nominal capacity.

Advantages:

-

immediate and reliable response

-

maximum vacuum stability

-

30-60 kPa regulation range

Membrane vacuum regolators

Milkline membrane valves are very efficient vacuum regulators which have an optimal quality/price ratio. They are able to maintain a constant vacuum level in the milking plant system, even under particularly difficult conditions. Membrane valves operate with a balancing membrane and a pneumatic actuator. Milkline membrane vacuum regulators capacity can reach 2.400 l/min.

Advantages:

-

optimal vacuum level monitoring

-

30-60 kPa regulation range

-

easy regulation

Cleaning and hygiene system

The milking parlors cleaning and hygiene is essential for the production of healthy and high quality milk. It must be performed to remove all milk residues which are responsible for the bacterial load of the milking plant.

It is thus important to equip the milking plant with an automatic and reliable cleaning system which can completely manage all cleaning cycle phases.

Milkline provides different options to help you keep your milking plants perfectly sanitized.

Clean-o-Matic is a washing unit that takes care of cleaning your milking plant. Its operation is very easy and reliable at the same time. Clean-o-Matic features a simple electro-mechanical control system where the cleaning operation is activated by simply pressing a button.

Advantages:

-

ease of use

-

complete cleaning program

-

suitable for any type of milking plant

-

possibility to increase water capacity

Clean-o-Matic STD

Clean-o-Tronic

Clean-o-Tronic is an automatic washing unit that is managed by a flexible and reliable electronic control. Each washing phase is completely programmable through PC or the EP4 portable device. 8 LEDs allow the display of the different washing phases.

Clean-o-Tronic efficient operation guarantees perfect performance of the washing cycle in every single phase.

Advantages:

-

possibility to perform either full or partial load cycles

-

cycle restart after possible shut off (no electric power supply)

-

water temperature display and optional boiler management

-

washing-phases display

-

suitable for any type and size of milking plant

-

PC or EP4 keyboard programmable

Combitronic

Combitronic is an entirely electronic control unit for total management of milking systems.

Combitronic is designed to control all milking and cleaning phases in a fully programmable way.

The device is equipped with a simple and intuitive keyboard for programming and a wide scrolling text LCD display.

Specifications:

-

separate pulsation management between milking and cleaning phase

-

milk pump control with overload protection

-

vacuum unit control with thermal protection

-

boiler control (optional) and wash water temperature control

-

automatic detergent dispenser

-

automatic recovery in case of power failure

-

programmable management of all milking phases

-

air injector control

-

input voltage monitoring with a shutdown in case of overvoltage.

Advantages:

-

easy to use

-

flexible: perfect adaptability to the system's needs

-

practical: it does not require other devices for programming

-

reliable, due to the use of high quality components

Accessories

In order to ensure that the milking system cleaning and sanitation operations are carried out in the best way, Milkline proposes to use specific water heaters and automatic detergent dosers.

Clean Hot

Clean Hot is a cleaning system for milking plants that uses high temperature water generated by a specific boiler.

The use of 92° hot water guarantees an exceptional reduction in bacteria and the option to avoid a daily use of detergents.

The system works both stand-alone and coupled to the cleaning device Clean-o-Tronic.

Advantages:

-

sterilization and cleaning in only 6/7 minutes

-

minimum water consumption

-

does not require detergents

Dosomatic 2

Dosomatic 2 is the device that allows management of detergent dosage in an accurate and precise way during the cleaning phases of the milking plant.

Dosomatic 2, to be combined with one of our automatic cleaning systems (Clean-o-Tronic, Clean-o-Matic, Combitronic), dispenses the exact amount of detergent necessary for an accurate cleaning of the milking plant.

Advantages:

-

automatic dispensing

-

exact dosage of products

(it avoids unnecessary wastes or risks due to inadequate dosage) -

ease of use

Water heater

It has been clearly demonstrated that milk contamination also takes place during milkings, for example if the milking plant isn't thoroughly cleaned.

The milk residuals that deposit in the pipes, favoring the growth of many bacteria; a cleaning temperature above 40°C can guarantee better cleaning of the milking plant. Milkline suggests the use of the water heater that steadily maintains the proper temperature during all the cleaning phases.

Advantages:

-

better cleaning

-

higher reduction of bacterial load

Tie stall barns

Although milking parlors today are technologically very advanced, many farmers still prefer tie stall barns. Tie stall barns feature a simple and effective structure which still offers the farmer many opportunities.

Milkline® proposes two types of systems, which can be both equipped with feeding and herd management systems for animal comfort and wellness.

Milkline bucket milking systems

The Milkline bucket milking system is a low-cost system for small size dairy farms. It substantially reduces milking time compared to the traditional milking method.

The system consists of a vacuum line and milking units equipped with milking buckets. The operator can use two or three milking units at the same time thus making the milking process more efficient. Milk collected in buckets will have to be transferred manually to the milk cooling tank.

The Milkline bucket milking system is an approved system and can be easily installed and it does not require special maintenance.

RTS pipeline milking systems

The RTS pipeline milking systems are designed for tie stall barns because they allow the cow to be milked at the stall. Working times are reduced compared to the bucket milking system because the emptying operation is not necessary. The RTS pipeline milking system consists of milk and vacuum lines and RTS clusters.

The milk line is characterized by a milk pipeline placed above the animals at 2 m maximum height. The pipes are given proper inclination to favour milk flow to the milk cooling tank.

Milkline proposes two types of milking units for the RTS pipeline milking systems:

-

Milking units with electronic pulsation, equipped with a rapid bayonet connection for vacuum line, milk line and power supply and with the Pulsator Stop function to prevent both overmilking and cluster fall off at the end of the milking.

-

The RTS200 milking unit features an ergonomic design with lighting display to read information. Although simple, the RTS200 milking unit has an FFS30 optical sensor to control milk flow and for the electronic measurement of milk production. The software can be personalized and customized using Palm.

-

The MC200/RTS milking unit is an alternative and cheaper choice compared to the RTS200. It enables the measurement of the milk production.

-

-

The MC200/RTS is an inexpensive pneumatic pulsation milking unit equipped with a simple connection for vacuum line and milk line.

Basic

With Milkline “Basic” portable milking machines your job will be easier and quicker!

The Milkline “Basic” portable milkers allow the production of high quality milk under the best hygienic conditions and reduces totally the stress for the animal.

Milkline “Basic” portable milker trolleys are entirely handmade in Italy, which improves their reliability and sturdiness. Thanks to the hot dip galvanization of the structure, which models the portable milker, milking becomes safer and secure.

These characteristics make the Milkline “Basic” portable milker a long lasting product. The Milkline “Basic” portable milker can be used for one or two animals at the same time, thanks to the different typologies of milking buckets. The portable milkers can be arranged with one or two 30 liter milking buckets each. Portabler milkers with stainless steel 25 liter milking buckets are available on demand.

Daily cleaning of the components involved in milking can be perfectly and easily performed.

Milkline “Basic” trolleys provide:

-

high milking performance anywhere

-

reliability and sturdiness - MADE IN ITALY

-

a wide range of products

-

easy handling and cleaning

-

available for cattle, sheep and goats

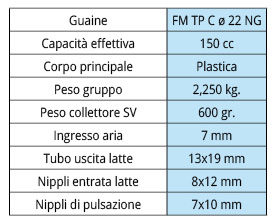

Economy 1E

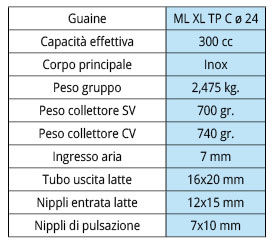

Mini 1E

Mini 2E

STD

Milkline “STD” portable milking machine will make your job easier and quicker!

Milkline “STD” portable milking machines are characterized by their easy use and maintenance. They are the best solution for any kind of dairy farm, large or small, pasture or stable based. Thanks to it sturdy frame, entirely made in Italy, and the sturdy components, it can be easily moved around even in hostile spaces, without sacrificing a quick and safe milking.

The sturdy materials, which the Milkline “STD” portable milking machine is made of, ensure a quality milk production anywhere, reducing the stress for the animals to a minimum. This means higher milk quality and production.

The 30 L transparent containers and the 40/50 L stainless steel containers enable minimizing waiting times and further reduce milking times.

With the portable milkers you can milk up to 32 cows, collecting the milk in 30 L transparent containers or 40/50 L stainless steel containers.

Milkline “STD” portable milking machines are available in different configurations: with one or two milking buckets and with gasoline engine.

Milkline “STD” portable milking machines provide:

-

Operator and animal's safety

-

Easy and sturdy mobility

-

Milking time reduction

-

Quality milk and higher milk production

-

High milking capacity

-

Entirely made in ITALY

Caddy

Compact

Economy

Jolly

Mini 1

Mini 2